What is Hot Melt Applicator System?

EGT's hot melt applicator system is a device that melts and pumps (pressurizes)

a thermoplastic resin (Hot Melt Adhesive) at a high temperature,

transports it to the desired destination, and dispensing it at the right time.

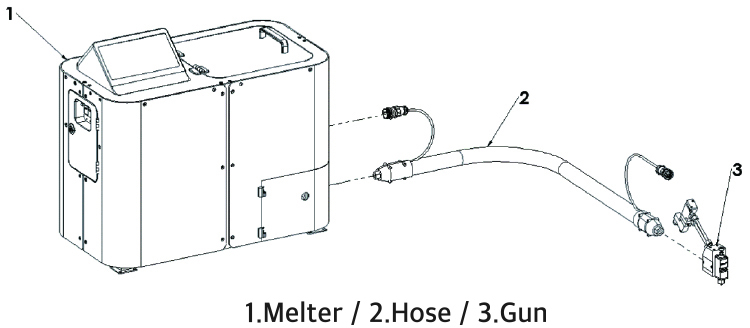

The system components include a melter, hoses, and dispensing guns, and the

temperature of each component can be individually controlled for safe and smooth

use of high-temperature, high-pressure, and high-viscosity Hot Melt Adhesive.

The hot melt applicator system can be widely applied and used in all

industries that require bonding and sealing using hot melt adhesives.